What is the key role of CASING HEAD SPOOL in the wellhead device of oil and gas wells?

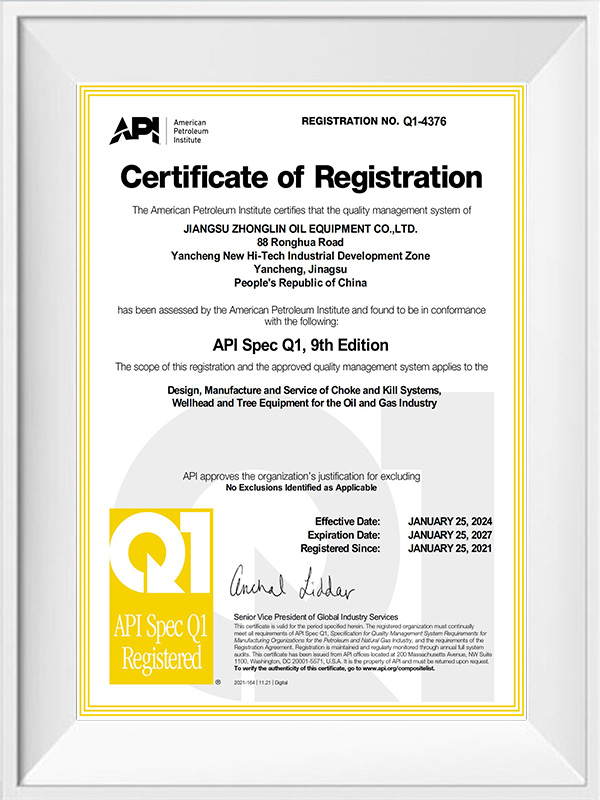

In the development and production process of oil and gas wells, the wellhead device plays a vital role. As an important part of the wellhead device, the key role of CASING HEAD SPOOL cannot be ignored. Jiangsu Zhonglin Oil Equipment Co., Ltd., as a professional oil and gas equipment supplier, is committed to providing customers with high-quality CASING HEAD SPOOL to ensure the safe and efficient operation of oil and gas wells.

1. Connection and support role

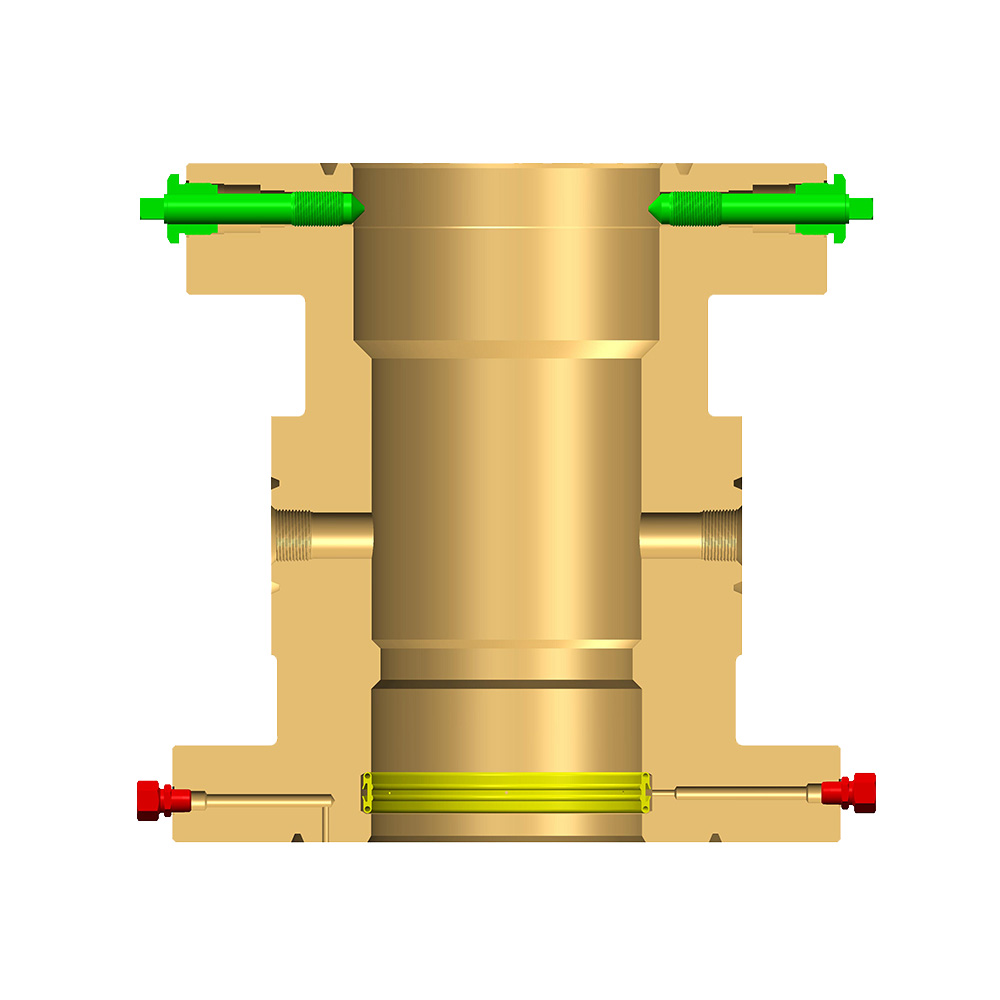

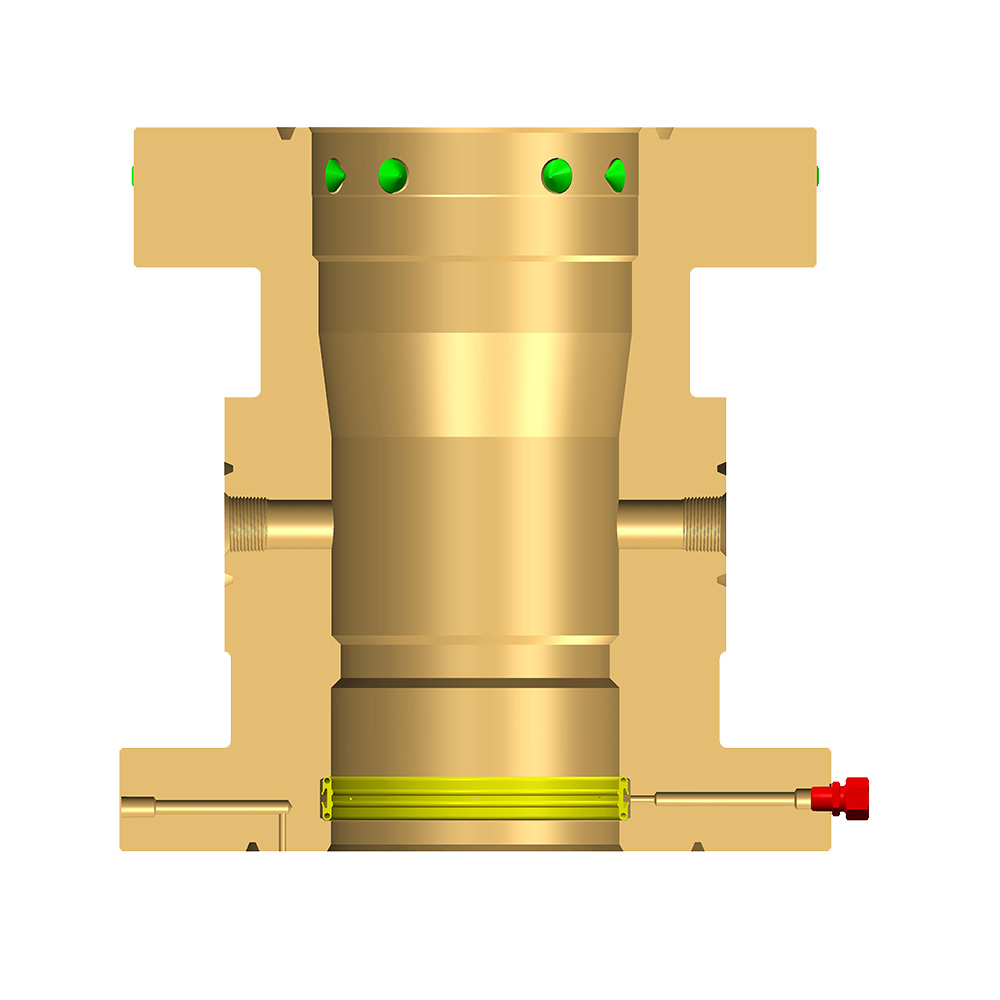

The primary key role of CASING HEAD SPOOL is to connect and support different layers of casing. During the construction of oil and gas wells, multiple layers of casing need to be lowered to protect the well wall and control the formation pressure. CASING HEAD SPOOL can firmly connect each layer of casing through its special structural design, and transfer its weight to the wellhead foundation, providing stable support for the entire wellhead device.

For example, its flange connection structure can be tightly connected with the casing head and other wellhead equipment to ensure the sealing and stability between the components. At the same time, its high-strength material and sturdy design can withstand the huge casing weight and formation pressure, ensuring that the wellhead device will not loosen or deform during long-term use.

2. Sealing and isolation function

Good sealing performance is one of the key requirements for wellhead devices in oil and gas wells. CASING HEAD SPOOL plays an important role in this regard. It can effectively seal the annular space between different layers of casing to prevent oil and gas leakage and the intrusion of formation fluids.

Jiangsu Zhonglin Oil Equipment Co., Ltd.'s CASING HEAD SPOOL adopts advanced sealing technology, such as high-performance rubber seals and metal sealing rings, which can maintain reliable sealing effects in various harsh working environments. This sealing and isolation effect can not only protect the safety of wellhead equipment and the surrounding environment, but also ensure the production efficiency and economic benefits of oil and gas wells.

3. Providing fluid channels and control interfaces

CASING HEAD SPOOL also provides important fluid channels and control interfaces for the production and control of oil and gas wells. It is usually equipped with multiple valves and connectors, which can be used to connect equipment such as well-killing manifolds and throttling manifolds to achieve pressure control and fluid regulation of oil and gas wells.

In an emergency, these valves and interfaces can be quickly closed to prevent oil and gas leaks and blowout accidents. At the same time, CASING HEAD SPOOL can also serve as a platform for installing various monitoring instruments and sensors to provide real-time data support for the production management of oil and gas wells.

4. Adapt to complex working conditions and environmental changes

The working environment of oil and gas wells is complex and changeable, including high temperature, high pressure, corrosion and other harsh conditions. CASING HEAD SPOOL must have good adaptability and be able to operate stably under these complex working conditions.

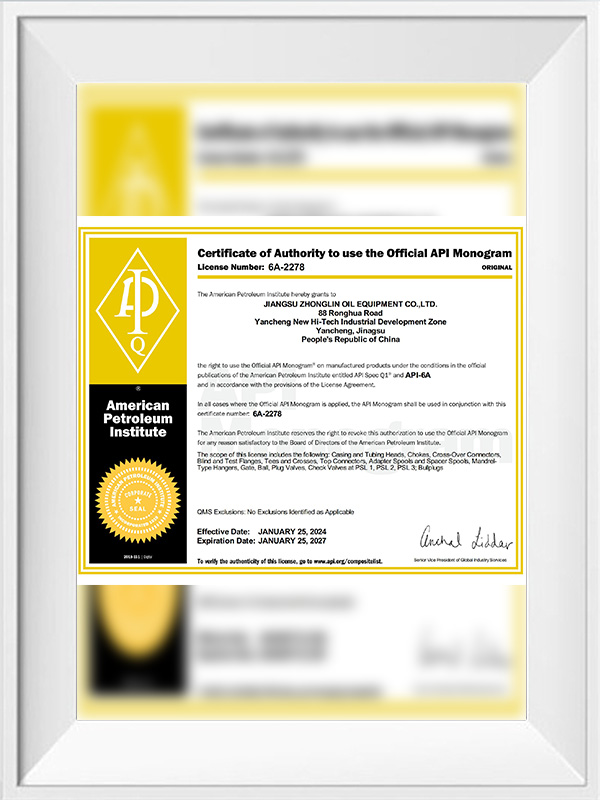

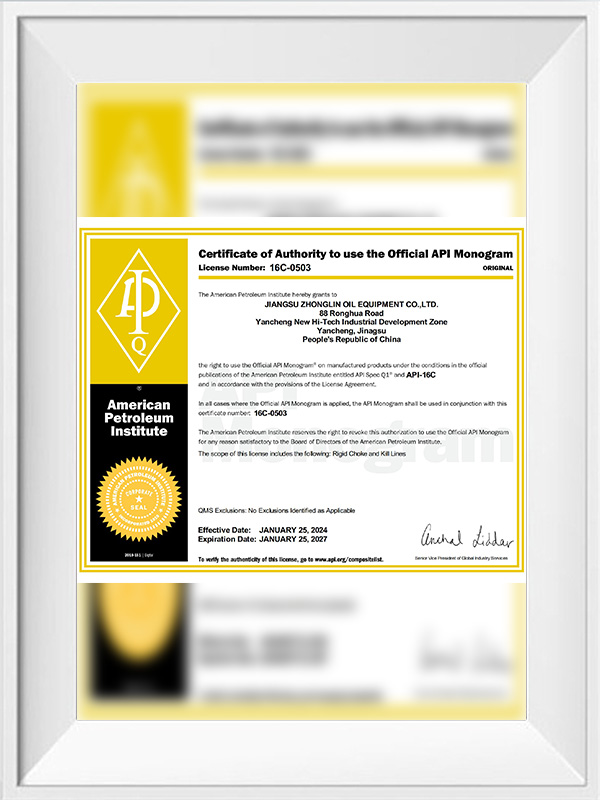

Jiangsu Zhonglin Oil Equipment Co., Ltd.'s products are strictly designed and manufactured in accordance with API standards, using high-quality materials and advanced processing technology to ensure that CASING HEAD SPOOL has excellent high temperature resistance, high pressure resistance and corrosion resistance. At the same time, the company can also customize the design according to the specific needs of customers to meet the special requirements of different oil and gas wells.

CASING HEAD SPOOL plays a key role in the wellhead device of oil and gas wells, such as connection and support, sealing and isolation, providing fluid channels and control interfaces, and adapting to complex working conditions and environmental changes. Jiangsu Zhonglin Oil Equipment Co., Ltd. will continue to be committed to providing customers with high-quality CASING HEAD SPOOL and excellent services and contribute to the development of the oil and gas industry.