What special design and safety requirements does SAFETY VALVE have for flammable and explosive media?

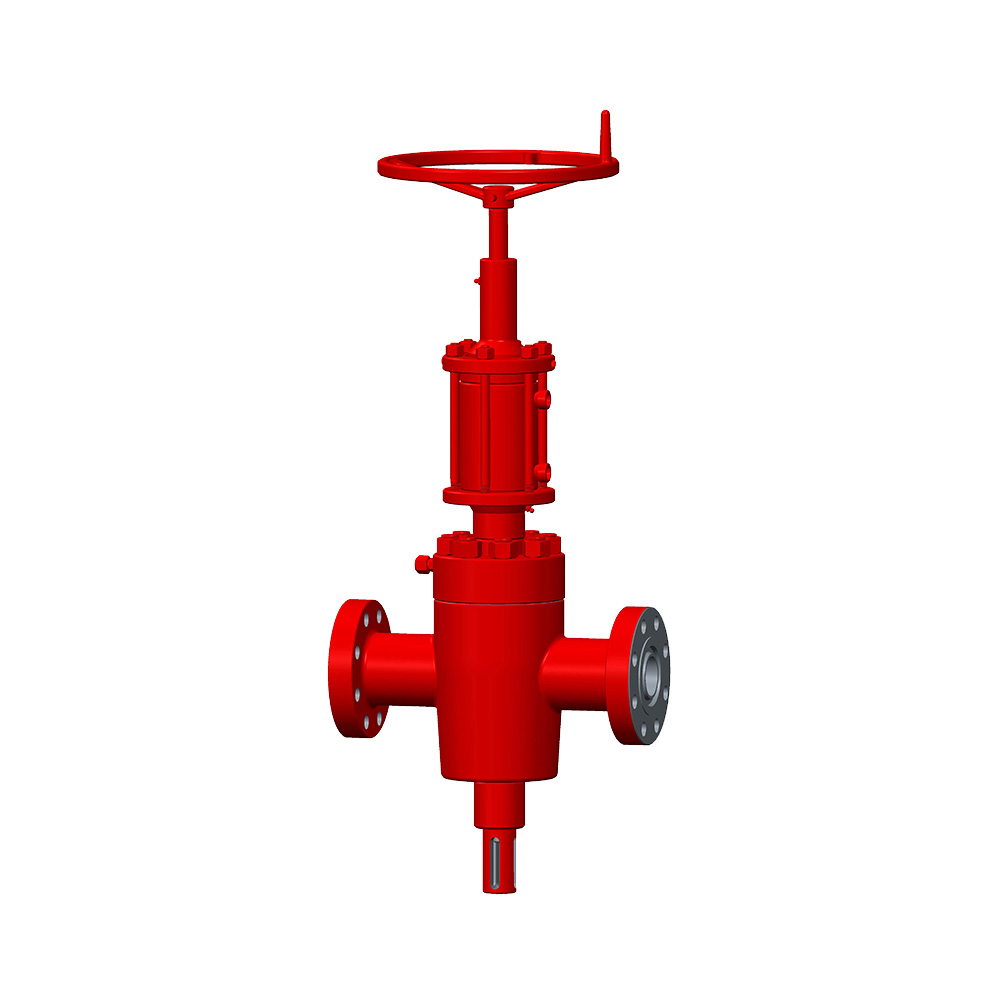

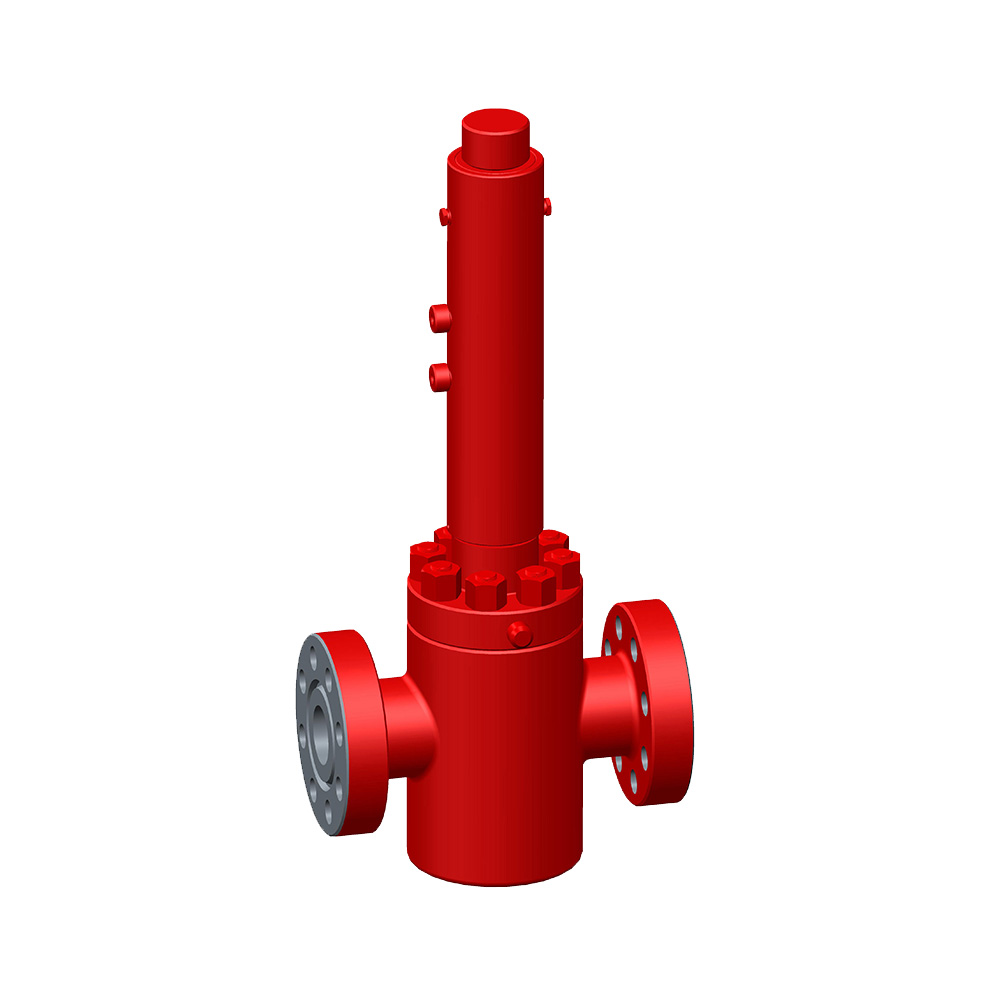

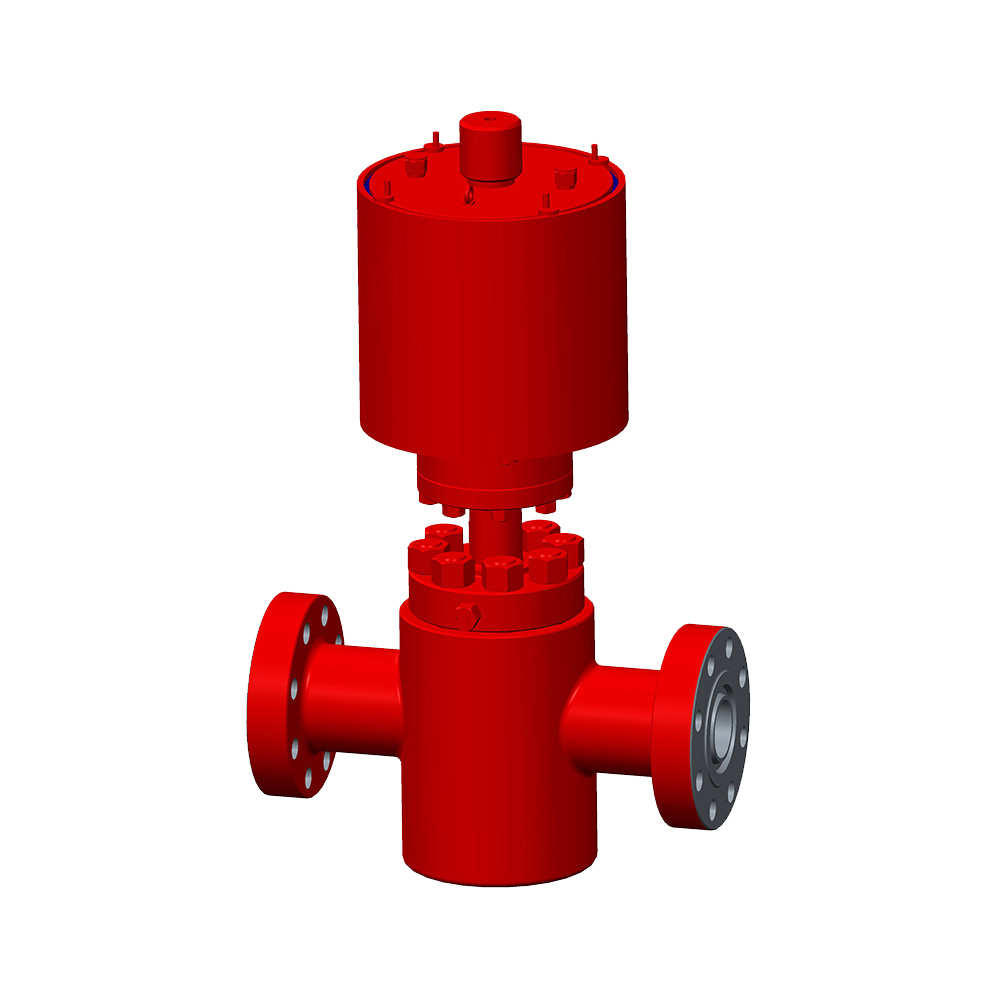

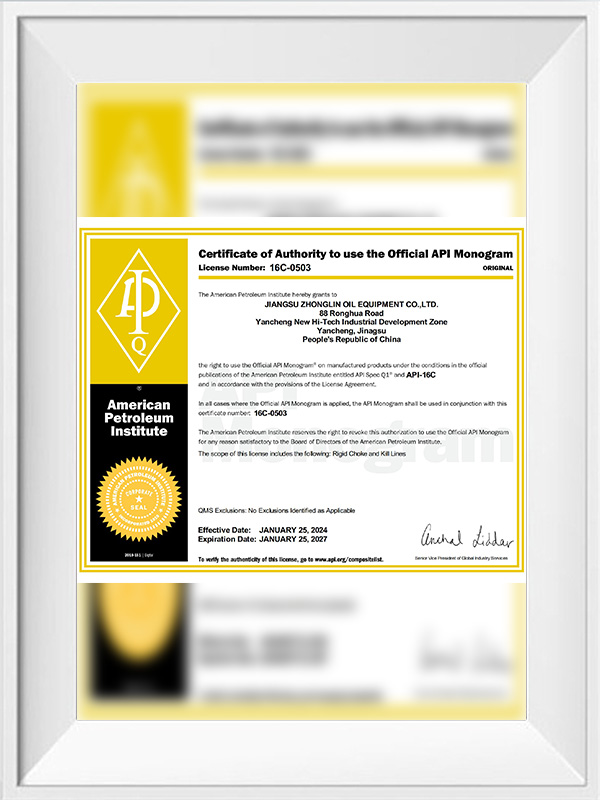

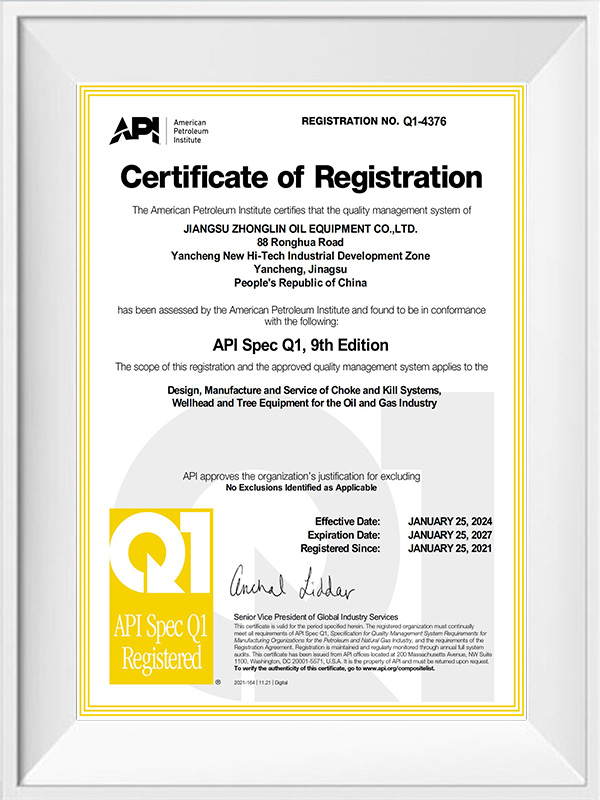

In the industrial field, handling flammable and explosive media is a very challenging task. As an important safety device, SAFETY VALVE plays a vital role in protecting the safety of equipment and personnel. Jiangsu Zhonglin Oil Equipment Co., Ltd., as a professional valve supplier and factory in China, has a deep understanding of the special needs for flammable and explosive media and provides customers with high-quality safety valve products.

1. Special design

Excellent sealing performance

For flammable and explosive media, preventing leakage is crucial. Jiangsu Zhonglin Oil Equipment Co., Ltd.'s safety valves use advanced sealing technology to ensure good sealing performance under various working conditions. For example, the use of special sealing materials and structural designs can effectively resist the erosion and pressure changes of the media and prevent leakage.

Fireproof design

When handling flammable and explosive media, once a fire occurs, the safety valve must be able to work normally in a high temperature environment to prevent the leakage of the media from causing greater danger. Our safety valves have been specially designed for fireproofing, which can maintain sealing in the event of a fire and prevent the spread of flames. At the same time, the material selection of the safety valve also takes into account the high temperature resistance to ensure that it will not deform or fail at high temperatures.

Quick response

When the system pressure exceeds the safety limit, the safety valve must be able to respond quickly and release the pressure in time to prevent equipment damage or explosion accidents. The safety valve of Jiangsu Zhonglin Oil Equipment Co., Ltd. adopts advanced spring design and valve core structure, which can respond to pressure changes instantly, open quickly and release pressure.

2. Safety requirements

Strict quality control

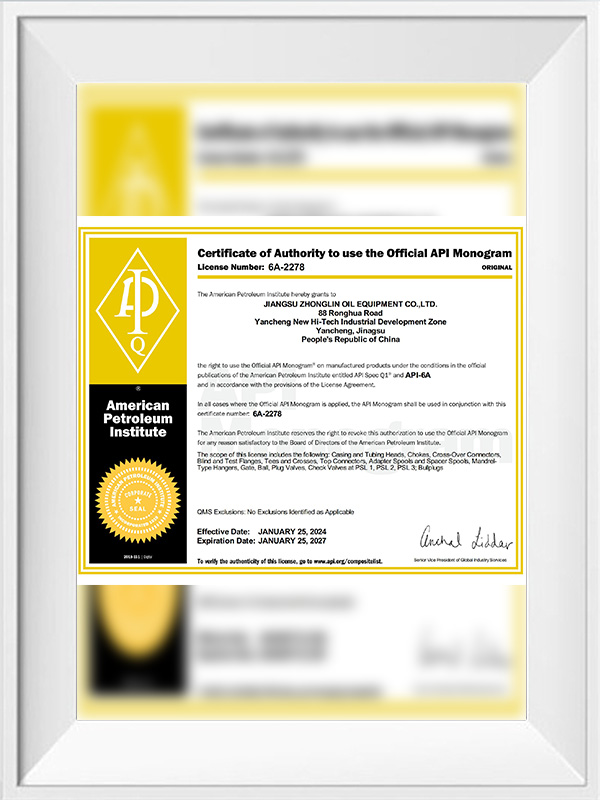

For safety valves that handle flammable and explosive media, quality control is essential. Jiangsu Zhonglin Oil Equipment Co., Ltd. strictly follows API and ISO standards for design, manufacturing and testing to ensure that each safety valve meets strict quality requirements. From the selection of raw materials to every link in the production process, strict quality control is carried out to ensure the reliability and safety of the safety valve.

Regular inspection and maintenance

In order to ensure the safety performance of the safety valve when handling flammable and explosive media, regular inspection and maintenance must be carried out. Jiangsu Zhonglin Oil Equipment Co., Ltd. recommends that customers regularly inspect and maintain the safety valve in accordance with relevant standards and specifications, including checking the sealing performance, spring elasticity, valve core action, etc. At the same time, we also provide professional testing and maintenance services to provide customers with all-round safety protection.

Professional installation and commissioning

Correct installation and commissioning are crucial to the safety performance of safety valves. Jiangsu Zhonglin Oil Equipment Co., Ltd. has a professional technical team that can provide customers with professional installation and commissioning services. Our technicians will formulate reasonable installation plans based on the specific needs and system characteristics of customers, and conduct strict commissioning and testing to ensure that the safety valve can work properly.

For flammable and explosive media, safety valves need to have special designs and strict safety requirements. As a professional valve supplier and factory, Jiangsu Zhonglin Oil Equipment Co., Ltd. always puts safety first, provides customers with high-quality safety valve products and professional services, and escorts the safety of industrial production.