What key role does CHECK VALVE play in preventing media contamination?

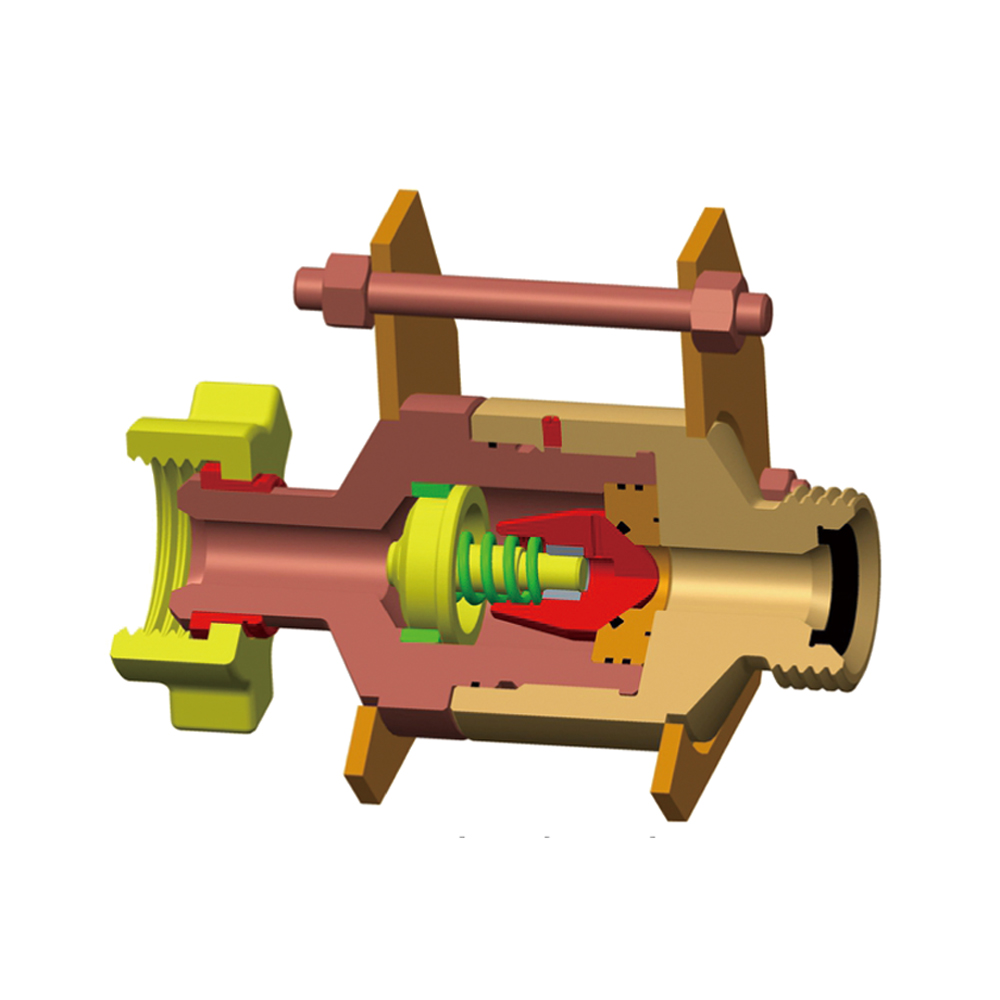

In the industrial field, especially in the process involving fluid transmission, it is crucial to prevent media contamination. As an important type of valve, CHECK VALVE plays a key role in preventing media contamination. Jiangsu Zhonglin Oil Equipment Co., Ltd., as a professional valve supplier and factory in China, is committed to providing customers with high-quality CHECK VALVE to ensure the safety and stability of industrial production.

1. Prevent media backflow and eliminate cross contamination

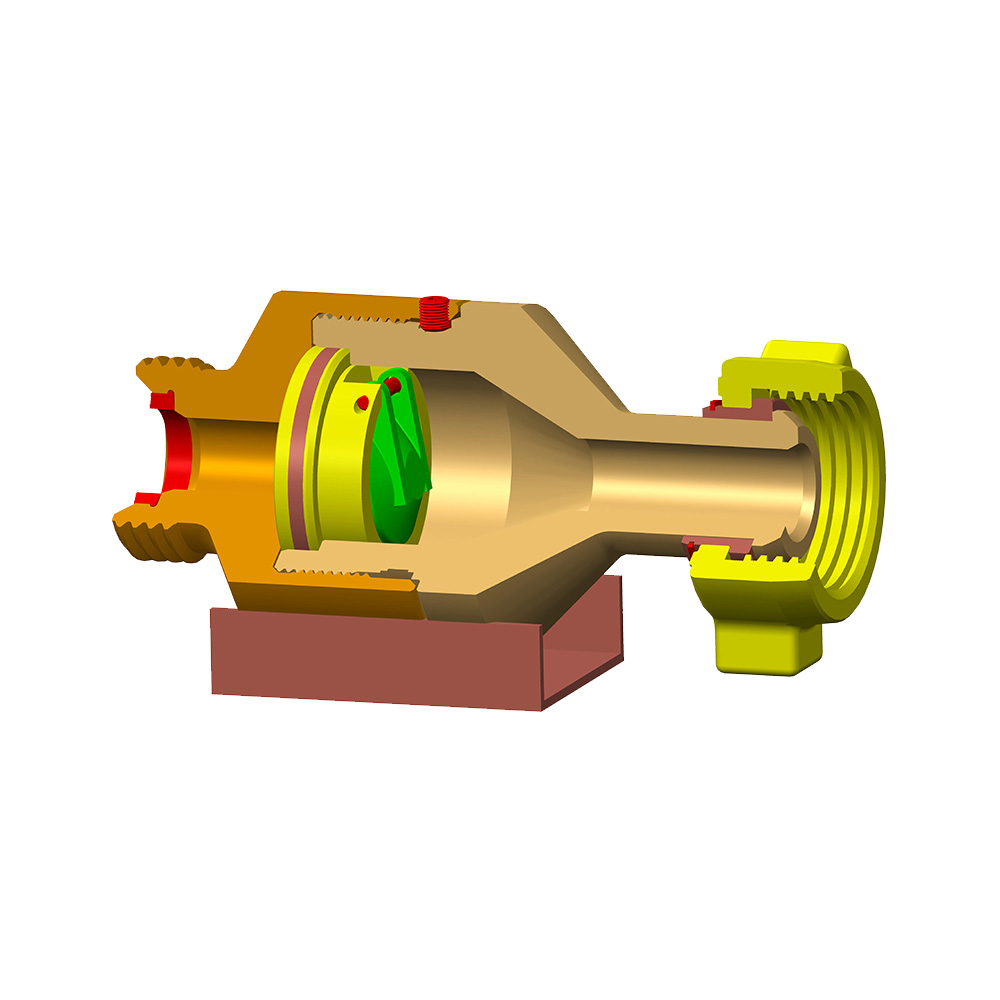

In fluid transmission systems, media backflow may cause serious contamination problems. Mixing media of different properties will not only affect product quality, but may also cause damage to equipment. One of the main functions of CHECK VALVE is to prevent media backflow. When the fluid flows in the normal direction, the check valve opens to allow the fluid to pass; when the fluid tries to flow back, the check valve quickly closes to prevent the reverse flow of the medium.

For example, in the petrochemical industry, when different batches of crude oil or chemical products are transmitted in pipelines, if backflow occurs, it may cause the mixing of media of different qualities, affecting the subsequent processing technology and product quality. Jiangsu Zhonglin Oil Equipment Co., Ltd.'s CHECK VALVE adopts advanced design and manufacturing technology to ensure that the valve can quickly and reliably prevent the backflow of the medium under various working conditions, effectively eliminating the risk of cross contamination.

2. Protect equipment and extend service life

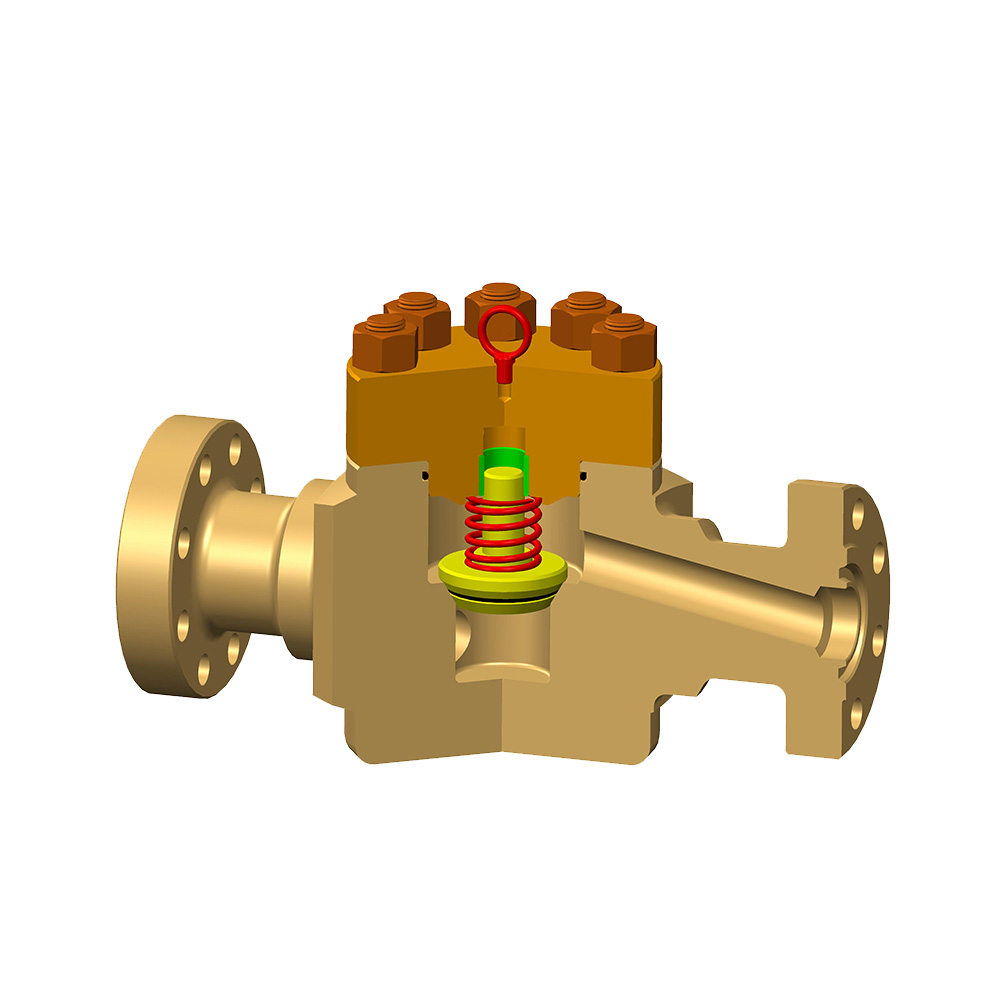

Media contamination not only affects product quality, but also may cause serious damage to the equipment. For example, the medium containing impurities entering the pump, compressor and other equipment may wear the internal parts of the equipment and reduce the performance and service life of the equipment. CHECK VALVE can avoid the impact and damage of the contaminated medium on the equipment by preventing the backflow of the medium.

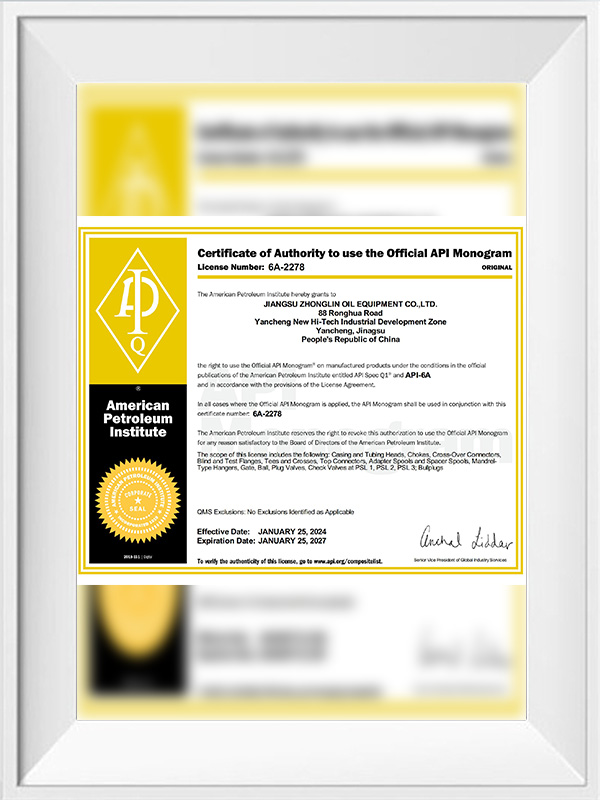

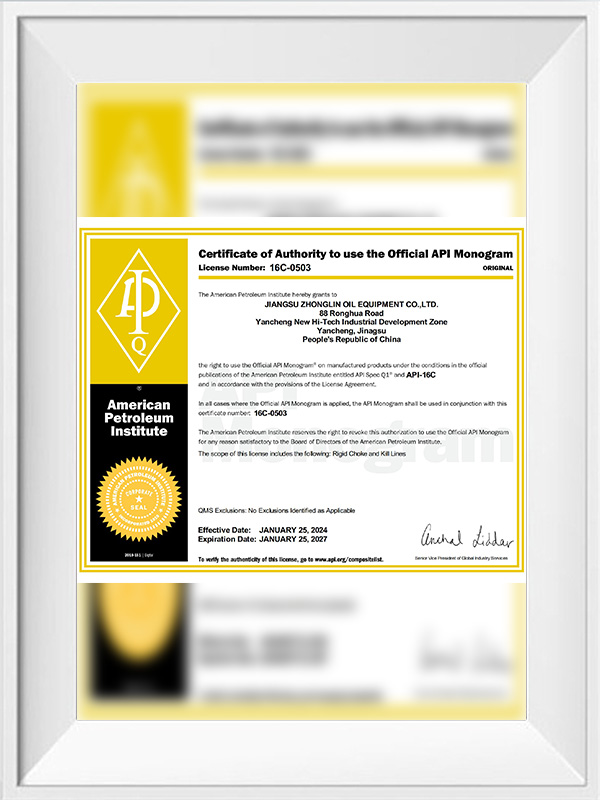

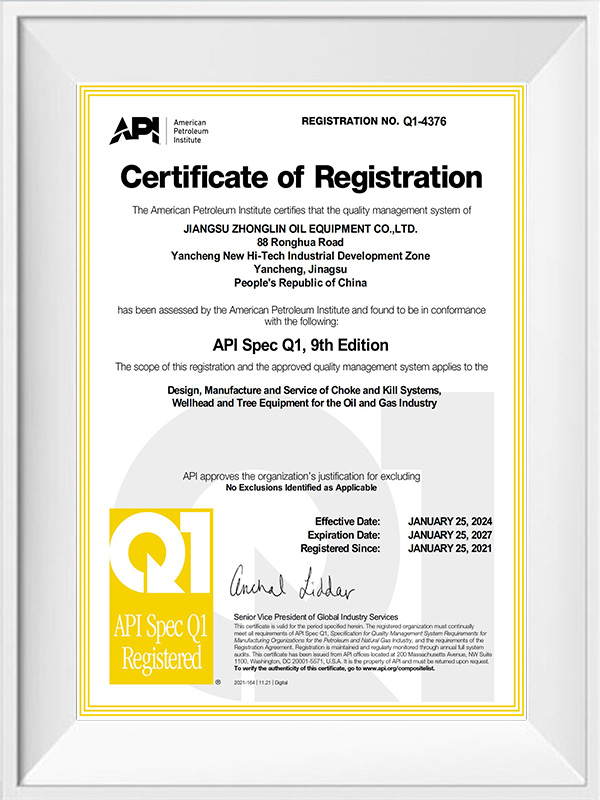

In addition, in some special applications, such as the food and pharmaceutical industries, the purity of the medium is extremely high. Any contamination may cause the product to be unqualified and even cause harm to human health. Jiangsu Zhonglin Oil Equipment Co., Ltd.'s CHECK VALVE is designed and manufactured in strict accordance with API and ISO standards, using high-quality materials and precision processing technology to ensure that the valve has good sealing performance and corrosion resistance, which can effectively prevent media contamination, protect equipment and extend the service life of the equipment.

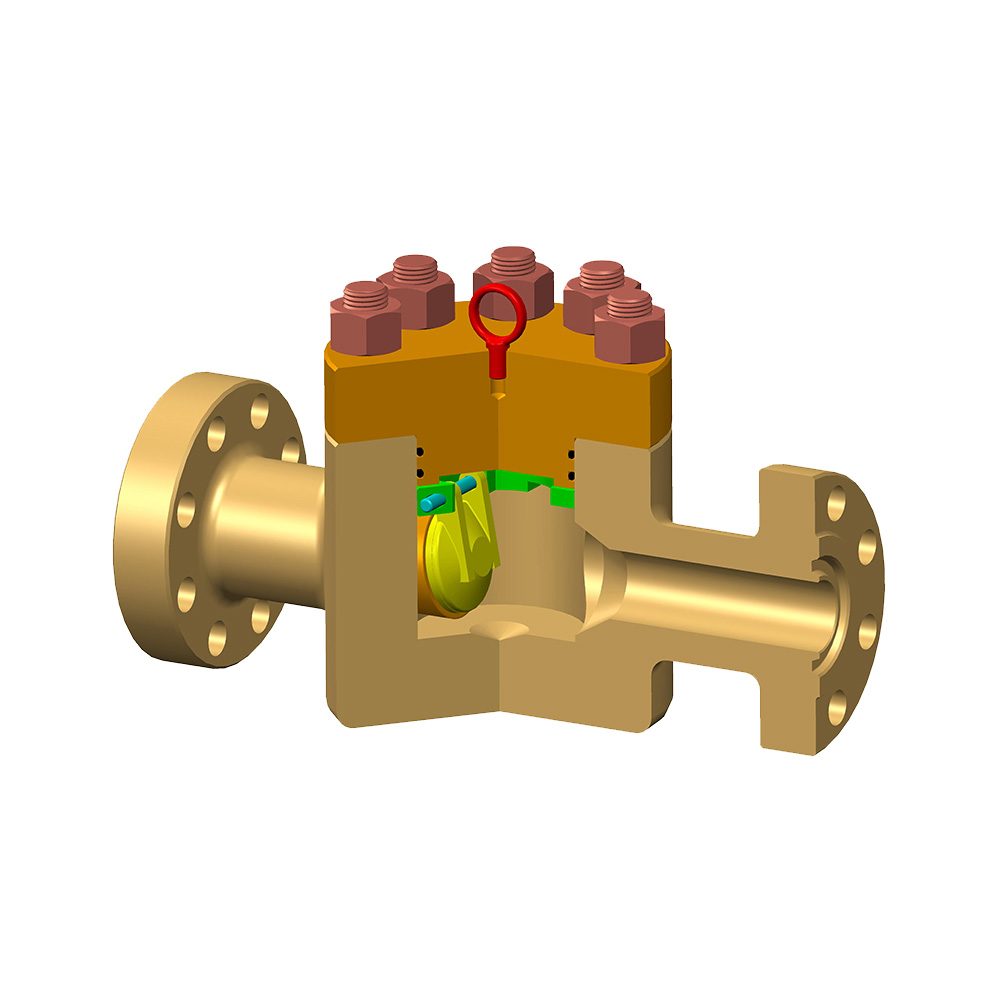

3. Improve the reliability and stability of the system

In industrial production, the reliability and stability of the system are crucial. Media contamination may cause equipment failure and production interruption, causing huge economic losses to the enterprise. The correct installation and use of CHECK VALVE can effectively prevent media contamination and improve the reliability and stability of the system.

Jiangsu Zhonglin Oil Equipment Co., Ltd. not only provides high-quality CHECK VALVE products, but also provides customers with professional technical support and after-sales service. The company's technical team can provide customers with customized solutions based on their specific needs to ensure that CHECK VALVE can perform at its best in different applications.

CHECK VALVE plays a key role in preventing media contamination. It can prevent media backflow and eliminate cross contamination; protect equipment and extend service life; and improve system reliability and stability. As a professional valve supplier and factory in China, Jiangsu Zhonglin Oil Equipment Co., Ltd. will continue to be committed to providing customers with high-quality CHECK VALVE products and services, and contribute to the safety and stability of industrial production.