In the intricate world of piping systems, selecting the correct valve is paramount for efficiency, safety, and cost-effectiveness. Two workhorses dominate industrial applications: the gate valve and the ball valve. While both serve the fundamental purpose of stopping or allowing flow, their design, operation, and ideal use cases differ significantly.

1. Design and Mechanism: The Core Distinction

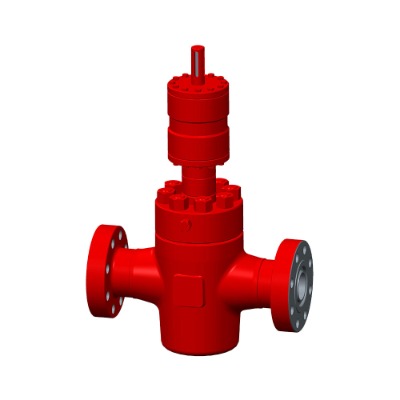

Gate Valve: This valve operates on a simple linear motion principle. A solid, wedge-shaped or parallel-faced "gate" moves perpendicularly to the flow path. Turning the handwheel raises or lowers this gate into or out of the path of the fluid. When fully open, the gate retracts completely into the valve bonnet, offering a straight-through, full-bore opening that minimizes pressure drop.

Ball Valve: As the name implies, this valve utilizes a spherical ball with a hole (bore) through its center. Rotating the ball 90 degrees via a lever or gear operator aligns the bore with the pipe for flow or positions the solid side of the ball perpendicular to block flow.

2. Function: Isolation vs. Control (and Isolation)

Gate Valve: Primarily for Isolation. Gate valves are designed to be either fully open or fully closed. Their slow operation minimizes water hammer. Gate valves excel in applications requiring minimal pressure drop when open and positive shut-off when closed, particularly with viscous fluids or slurries where the sliding gate can cut through deposits. They are not suitable for throttling or regulating flow. Partial opening causes vibration, rapid wear of the gate and seats, and potential damage to the valve body.

Ball Valve: Excellent Isolation & Limited Throttling. Ball valves provide positive, bubble-tight shutoff with a simple 90-degree turn, making them ideal for quick isolation. Their design generally allows for some throttling capability, though it's not their primary function and can cause erosion of the soft seats over time, especially with high-velocity flows. They offer reliable sealing in both low and high-pressure applications.

3. Operation and Speed

Gate Valve: Slow Operation. Opening or closing a gate valve requires multiple turns of the handwheel (often several revolutions). This slow operation is beneficial for preventing water hammer but is impractical where rapid shut-off is critical.

Ball Valve: Fast Operation. The quarter-turn (90-degree) operation of ball valves allows for extremely quick opening and closing, making them ideal for emergency shut-off applications.

4. Flow Characteristics and Pressure Drop

Gate Valve: Minimal Pressure Drop (When Fully Open). The full-bore design of a gate valve means that when fully retracted, the flow path is virtually unrestricted, resulting in very low pressure loss – a key advantage in long pipelines or systems where energy efficiency is critical.

Ball Valve: Generally Full Bore or Reduced Bore. Ball valves are available as "full port" (bore diameter matches the pipe ID) or "reduced port" (bore diameter smaller than pipe ID). Full-port ball valves offer pressure drop similar to a gate valve. Reduced-port versions introduce higher pressure drop but are smaller and cheaper.

5. Sealing and Maintenance

Gate Valve: Sealing relies on the wedging action of the gate against the seats. While effective when new, the sliding motion can lead to wear over time, potentially compromising the seal. Repacking the stem seal is common maintenance. Rising stem designs provide a visual indicator of valve position.

Ball Valve: Sealing is achieved by the ball pressing against resilient (often PTFE) seats. This design provides excellent, bubble-tight shutoff. Seats can wear, especially if used for throttling, but are generally replaceable. Stem seals also require occasional maintenance.

6. Typical Applications: Where Each Shines

Gate Valve:

Water distribution networks (main lines, pump discharge)

Power plants (steam service, feedwater)

Oil & Gas (isolation on crude lines, viscous fluids)

Slurry and high-solids applications

Applications requiring full bore, low pressure drop

Ball Valve:

Process industries requiring quick shut-off (chemical, petrochemical)

Fuel gas lines

Instrument isolation

Cooling water systems

On/Off duties in HVAC

Applications requiring bubble-tight sealing

The gate valve remains indispensable for applications demanding minimal flow restriction and robust isolation in fully open or closed positions, especially with challenging fluids. Ball valves offer unparalleled speed and sealing reliability for on/off duties. Understanding these core differences – the linear motion versus quarter-turn, the full-bore design versus sealing mechanism, and their respective strengths in isolation versus speed – empowers professionals to select the optimal valve, ensuring system integrity, safety, and long-term performance.